Steel Industry and Surface Treatment

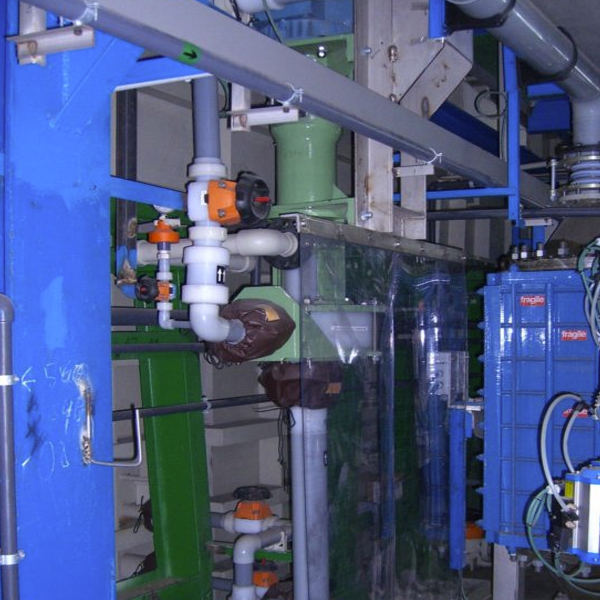

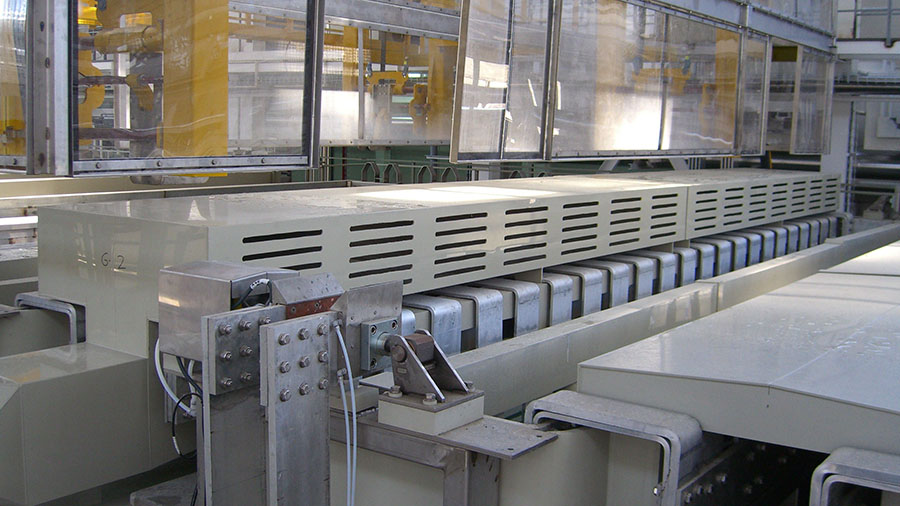

The steel industry and in particular pickling lines both steel and stainless steel, galvanizing or anodized plants and acid recovery plants, have problems and applications that TECNIUM can solve. Acid pumping and storage and gas collection and treatment plants, are some examples of projects for this sector.

Applications

Gas Treatment on Metalurgical Process

Scrubbing systems for gas treatment on installation for galvanization, anodizing, pickling, aerosols, chromates,

Recirculation Pumps

Gas Treatment Technologies

Absorption: TECNIUM-CHEM

Under this technology Tecnium supply multiple systems for gas treatment and odor control based on water or chemical absorption using wet scrubbers, jet venturis and cyclons.

Plastic Pumps

Vertical Sump Pumps

Wide range of plastic sump pumps cantilevered shaft with dry running possibility, specially indicated for liquids with particles.

Flows up to 500 m3/h and heads up to 100 mlc

Vertical External Pumps

Range of external vertical pumps, glandless with dry running capability, specially indicated for liquids with particles.

Flows up to 1.200 m3/h and heads up to 150 mlc

Process Pumps

Standardized pumps as per EN 22858 / ISO-5199. Heavy duty process pumps for a continuos operation. Wide range of plastic materials and mechanical seals, selected chemically and mechanically to resist the handled fluid. Flows up to 1.500 m3/h and heads up to 120 mlc.

Direct Coupled Pumps

Plastic Pumps: BH Serie Direct coupled pumps. Hydraulic performance and dimensions as per EN 22858. Economic solution […]

Plastic / FRP Tanks

Plastic / FRP Tanks

Plastic / FRP Tanks Corrosion resistant equipment Standard tanks Reactors and vessels Silos Decanters, thickeners Tank capacities […]

Valves, Grattings, Ladders and Handrails

Range of plastic valves: automatic regulation, safety, relief.

Grattings, ladders and handrails manufactured in GRP.

Corrosion resistant levels, optical, continuos electric reading or alarm

Plastic fans

Pulleys and Belts Coupled

Range of plastic fans corrosion resistant for medium/high pressures. Flows up to 120.000 m3/h and pressures up to 7.000 Pa.

Direct Coupled

Range of corrosion resistant plastic fans for medium/low pressure. Flows up to 40.000 m3/h and pressures up to 4.500 Pa.

Other sectors available

Extensive experience and know-how allows us to propose the most optimized solution for gas treatment, odor control and storage and pumping of corrosive fluids.