Pulp & Paper

The paper industry is intensive in the use of water and energy. The processes of digestion and pulp bleaching effluents that must be addressed before reintroduction into the mill.

TECNIUM has several references for such paper mills.

Applications

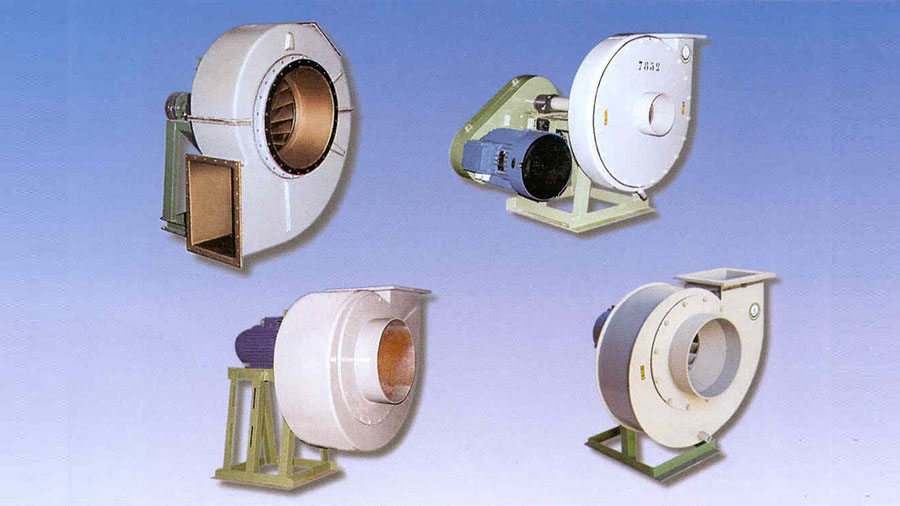

Fans for ClO2

The use of chlorine dioxide to bleach the paper pulp generes a waste gas flow that is necessary to treat before being throwed to the atmosfere. Tecnium supplies the fans to handle this type of toxic and corrosive gases

Gas Treatment Technologies

Biotrickling: TECNIUM BIO-TR

The high efficiency of BIO-TR enables the reconversion of your chemical scrubber installation by removing the reagents consumption and so removing the chemical products storage in your facilities.

Absorption: TECNIUM-CHEM

Under this technology Tecnium supply multiple systems for gas treatment and odor control based on water or chemical absorption using wet scrubbers, jet venturis and cyclons.

Other sectors available