Storage Tank Farms

TECNIUM can offer wide experience in storage liquids of corrosive or toxic nature. To that purpose manufactures and supplies a wide range of tanks, reactors and other vessels built in materials suitable for a very good chemical and mechanical resistance.

All tanks are constructed under strict international standards such as:

- EN-13121

- BS-4994

- NFT-57900

and codes of construction as per:

- EN-13121

- UIC nº 7

- UIC DT 15

- DVS

Mechanical and sismic calculations can be provided.

Following such standards and codes, our wall constructions are made with two types of barriers, one chemical with the mission to resist the chemical activity of liquids contained and other mechanical with the mission to provide the mechanical resistance of the tank.

Our welders and laminators are duly homologated and certified by an external notification body.

TECNIUM can supply different types of tanks, both vertical and horizontal and with individual capacities up to 200 m3, using different standard diameters up to 4.200 mm.

TECNIUM can also complements the supply with related equipment such as centrifugal pumps for loading tanks, all types of valves, pipes in plastic, structures, grates and access ladders in polyester and instrumentation, in order to complete installation.

TECNIUM can also supply the project to comply with existing Directives of Chemical Products Storage or facilitate the manufacturing certificates needed to proceed further to the legalization of the equipment.

TECNIUM has a very extensive list of references of such type of storage parks due to its already long career as a manufacturer.

Materials of Construction

- Polyester Resins Reinforced with Fiberglass (FRP)

- PVC

- PVDF

- PE

- E-CTFE

More information

Give us your contact details and we will advise you on the best solution for your application.

View also

How Gas Scrubbing Technologies Will Drive Decarbonisation in the Chemical Sector

Decarbonisation as the Urgent Challenge for the Chemical Industry The chemical industry is entering one of the most transformative decades in its history. As regulatory pressure intensifies and global climate targets advance, [...]

Tecnium to attend PCH Meetings 2025 in Lyon

Leading Innovation in Chemical Process Equipment Tecnium will participate in the 21st edition of PCH Meetings, the leading international business convention for process, chemical, petrochemical, and pharmaceutical industries, to be held on [...]

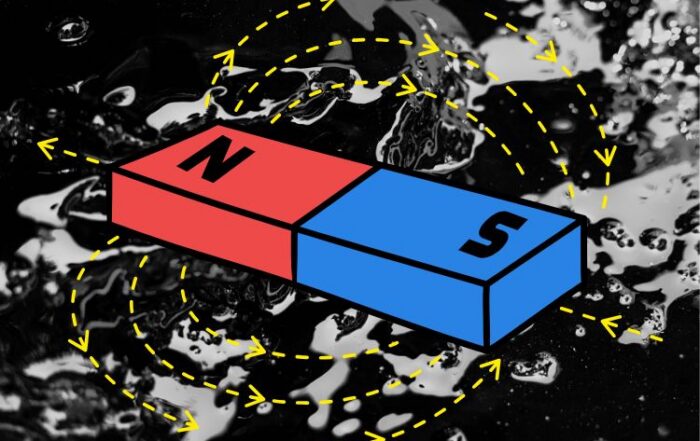

Magnetic Drive Pumps: The Science Behind Leak-Free Chemical Transfer

Why Magnetic Drive Technology Matters In industrial environments where safety, reliability, and chemical containment are critical, even a small leak can have major consequences. Traditional centrifugal pumps, which rely on mechanical seals [...]

Biofiltration for Air Pollution Control

Introduction to Biofiltration and Air Pollution Control Air pollution control is a persistent challenge across multiple industries — from wastewater treatment to chemical manufacturing, food processing, and beyond. As regulations grow stricter [...]

ECHA 2025 Report

Why the ECHA 2025 Report Matters The European Chemicals Agency (ECHA) plays a central role in regulating the safe use of chemicals across the European Union. Through its guidance, risk assessments, and [...]

A Key Element for Environmental Protection in WWTPs

Why Gas and Odour Emissions in WWTPs Are an Environmental Issue Wastewater treatment plants (WWTPs) play a critical role in safeguarding public health and the environment. However, the treatment process itself can [...]