Process Pumps – BN Series

Standardised chemical process pumps according to ISO 2858 / EN 22858 / ISO 5199

The BN Series from Tecnium are heavy-duty plastic process pumps specifically designed for the continuous transfer of corrosive and abrasive fluids under demanding industrial conditions. Built in solid thermoplastic materials, these pumps combine outstanding chemical resistance with robust mechanical performance, ensuring safe, long-term operation in aggressive environments.

Design and Construction

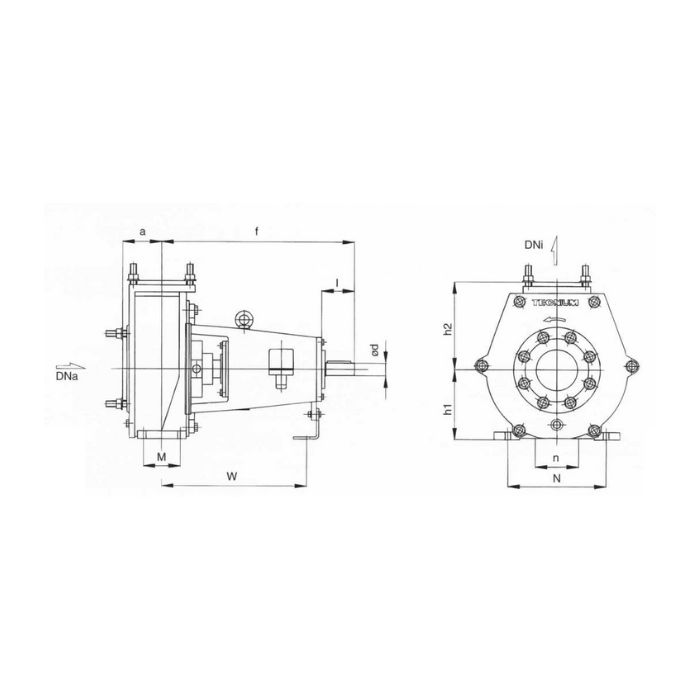

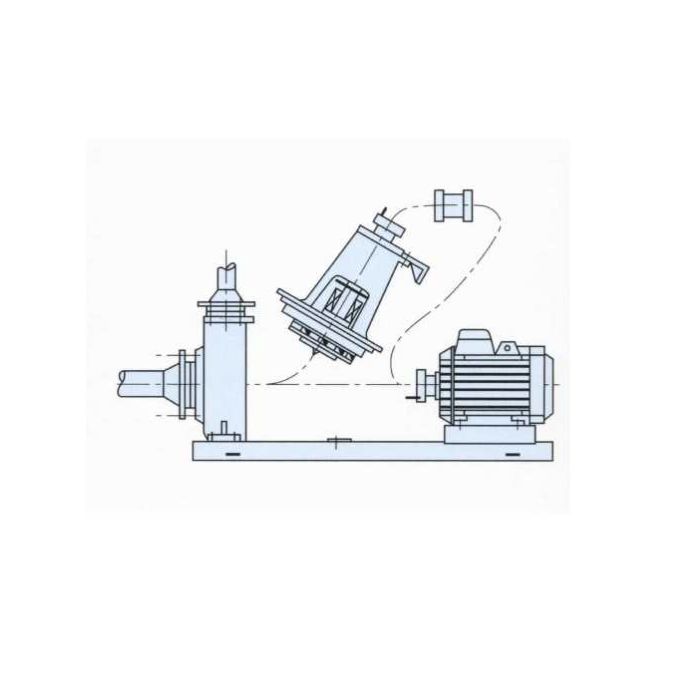

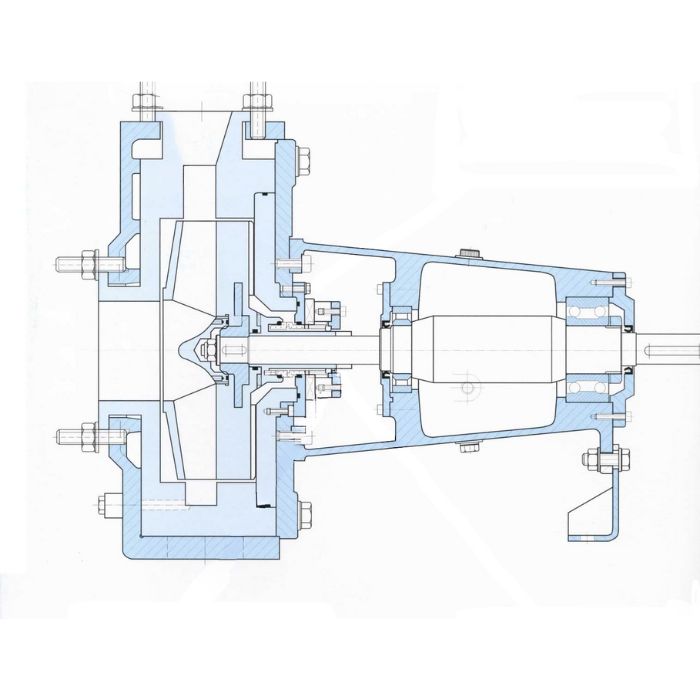

The BN Series features a solid monoblock casing machined from a single thermoplastic block, providing maximum rigidity and chemical resistance. The impeller is closed, guaranteeing high hydraulic efficiency and reduced turbulence. A steel shaft completely protected by a removable plastic sleeve prevents corrosion and facilitates maintenance. The modular back pull-out design allows full dismantling of the rotor group without disconnecting suction or discharge lines.

Performance and Range

- Flow rate: up to 1,500 m³/h (6,600 gpm)

- Head: up to 120 mcl (394 ft)

- Nominal pressure: PN 10

- Maximum operating temperature: up to 90 °C, depending on the thermoplastic material used

- Configuration: single-stage, end-suction, back pull-out design

- Impeller: closed type for optimal hydraulic efficiency

Applications

Tecnium BN pumps are ideal for industries requiring maximum resistance to corrosive and abrasive substances, including:

- Chemical and pharmaceutical industries

- Water and wastewater treatment

- Surface finishing and galvanisation

- Fertiliser and phosphoric acid production

- Power generation and cooling circuits

Mechanical Seal Options

The BN series can be fitted with a wide variety of mechanical seals depending on the application and chemical compatibility:

- IP: internal single mechanical seal (SiC/SiC)

- IF: internal single mechanical seal (PTFE/Ceramic)

- SF: external single mechanical seal (PTFE/Ceramic)

- DE: double external mechanical seal

The mechanical seal housing is designed to isolate the sealing area from plastic stresses, improving reliability and preventing deformation during operation.

Downloads:

Process Pumps Brochure – English – 179 KB

Plastic Pumps Catalogue – English – 1.17 MB

Standard Plastic Centrifugal Pumps Catalogue –English – 1.6 MB

Technical Advantages

- Torque transmission by steel core and keyed impeller connection.

- Independent removable shaft sleeve, isolated from the impeller.

- DIN 2501 flanges standard (ANSI 150 lbs optional).

- Minimal maintenance even under the harshest operating conditions.

- Corrosive dispersion prevented through fully sealed mechanical cover design.

- CE compliant according to the European Machinery Directive 2006/42/EC.

- ATEX-certified versions available (Directive 2014/34/EU) for use in explosive atmospheres.

Available Materials

The BN Series pumps are available in a full range of corrosion-resistant thermoplastics to ensure maximum compatibility with industrial fluids:

- PP (Polypropylene)

- UHMW-PE (Ultra-High Molecular Weight Polyethylene)

- PVDF (Polyvinylidene Fluoride)

- E-CTFE (Ethylene Chlorotrifluoroethylene)

- PVC (Polyvinyl Chloride)

- PTFE (Polytetrafluoroethylene)

Mixed configurations are also available, allowing the combination of different thermoplastics — for example, PP or UHMW-PE casings with PVDF or PTFE wetted parts — to achieve optimal chemical compatibility and cost efficiency according to process requirements.

More information

Give us your contact details and we will advise you on the best solution for your application.

View also

How Gas Scrubbing Technologies Will Drive Decarbonisation in the Chemical Sector

Decarbonisation as the Urgent Challenge for the Chemical Industry The chemical industry is entering one of the most transformative decades in its history. As regulatory pressure intensifies and global climate targets advance, [...]

Tecnium to attend PCH Meetings 2025 in Lyon

Leading Innovation in Chemical Process Equipment Tecnium will participate in the 21st edition of PCH Meetings, the leading international business convention for process, chemical, petrochemical, and pharmaceutical industries, to be held on [...]

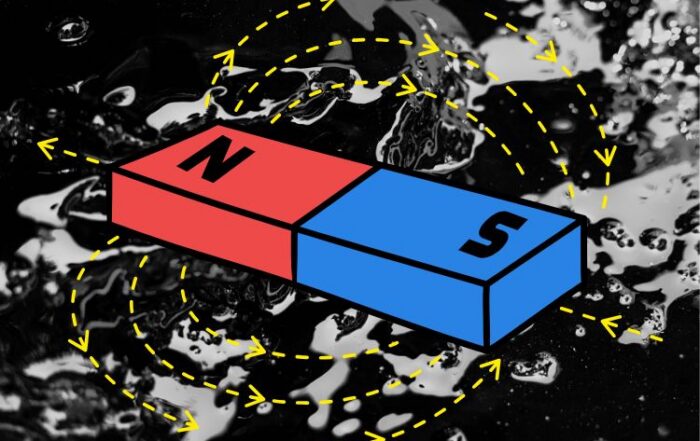

Magnetic Drive Pumps: The Science Behind Leak-Free Chemical Transfer

Why Magnetic Drive Technology Matters In industrial environments where safety, reliability, and chemical containment are critical, even a small leak can have major consequences. Traditional centrifugal pumps, which rely on mechanical seals [...]

Biofiltration for Air Pollution Control

Introduction to Biofiltration and Air Pollution Control Air pollution control is a persistent challenge across multiple industries — from wastewater treatment to chemical manufacturing, food processing, and beyond. As regulations grow stricter [...]

ECHA 2025 Report

Why the ECHA 2025 Report Matters The European Chemicals Agency (ECHA) plays a central role in regulating the safe use of chemicals across the European Union. Through its guidance, risk assessments, and [...]

A Key Element for Environmental Protection in WWTPs

Why Gas and Odour Emissions in WWTPs Are an Environmental Issue Wastewater treatment plants (WWTPs) play a critical role in safeguarding public health and the environment. However, the treatment process itself can [...]

Green ammonia: The fuel of the future

What is green ammonia and how is it produced? Green ammonia is an environmentally friendly alternative to conventional ammonia, produced without fossil fuels or carbon emissions. While traditional ammonia synthesis relies on [...]

Chemical sector decarbonisation

How Scrubbing Technologies can help Despite growing environmental awareness and ambitious climate targets, the chemical industry remains one of the most fossil-fuel-dependent sectors in Europe and beyond. From ammonia to methanol, production [...]

The Critical Chemical Alliance

Europe’s Industrial Comeback Strategy In a decisive move to reinforce industrial resilience and regain sovereignty in key manufacturing sectors, the European Commission has announced the upcoming launch of the Critical Chemical Alliance. This [...]