What is green ammonia and how is it produced?

Green ammonia is an environmentally friendly alternative to conventional ammonia, produced without fossil fuels or carbon emissions. While traditional ammonia synthesis relies on hydrogen derived from natural gas (a process that emits significant CO₂), green ammonia uses hydrogen obtained through the electrolysis of water powered by renewable energy sources. This hydrogen is then combined with nitrogen from the air via the well-known Haber-Bosch process — but without the carbon footprint.

The result is a completely decarbonised ammonia molecule (NH₃), identical in structure to its conventional counterpart but fundamentally different in environmental impact. Green ammonia production eliminates CO₂ emissions at source and contributes to a circular, sustainable industrial model.

The environmental benefits are significant:

With rising global demand for hydrogen carriers and low-carbon feedstocks, green ammonia is quickly becoming a key pillar in the energy transition.

Industrial applications of green ammonia

Green ammonia is more than just a low-emission chemical — it’s a strategic molecule with multiple industrial applications. As industries around the world accelerate their decarbonisation efforts, green ammonia is emerging as a clean and versatile alternative in sectors that are traditionally hard to abate.

In short, green ammonia acts as a decarbonising agent across various industries, unlocking new possibilities for cleaner production systems and energy resilience.

The Saudi Arabia project: Técnicas Reunidas and Sinopec lead a global milestone

In early 2024, the Spanish engineering firm Técnicas Reunidas, in partnership with Sinopec Engineering Group, was awarded the largest green ammonia plant project in the world. Located in the industrial city of Yanbu, on the Red Sea coast of Saudi Arabia, the facility represents a turning point in the global transition to clean hydrogen derivatives.

The plant is part of Saudi Arabia’s national hydrogen strategy, which aims to position the country as a leading exporter of green fuels to Europe and Asia. The project will produce ammonia using hydrogen obtained via electrolysis powered by renewable energy, avoiding any use of fossil fuels in the process.

Key figures:

This megaproject not only showcases the scalability of green ammonia but also creates a blueprint for future facilities worldwide. For suppliers of industrial infrastructure — especially those with expertise in gas treatment, corrosion-resistant equipment, and emission control systems — the project presents a unique opportunity to contribute to the decarbonised economy.

How Tecnium’s Expertise Supports Green Ammonia Projects

Building a green ammonia plant involves a series of technically demanding stages, from hydrogen production via electrolysis to nitrogen separation, synthesis, purification, and safe storage. Each of these steps generates by-products, emissions, and operational challenges that require robust environmental and chemical handling systems — precisely where Tecnium’s expertise comes into play.

Proven Solutions for Corrosive Fluid and Gas Management

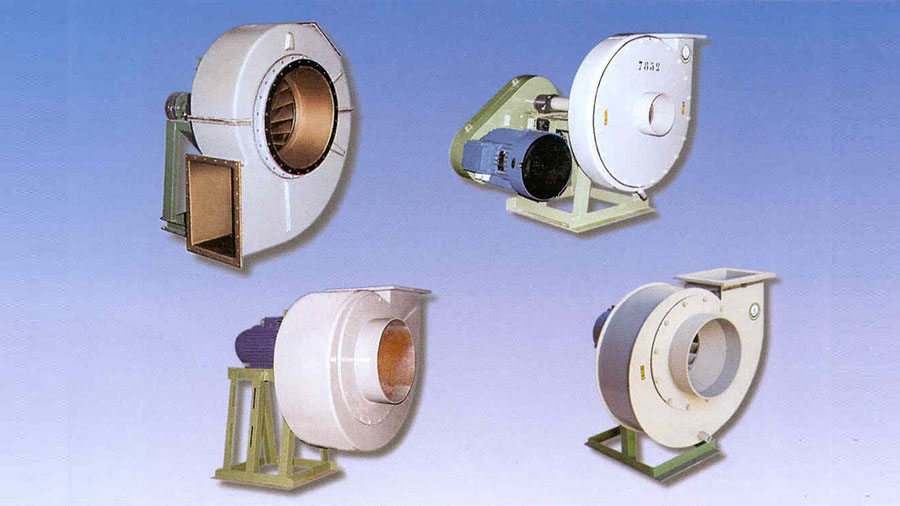

Tecnium provides industrial equipment designed to operate in harsh chemical environments. In the context of a green ammonia facility, the following product lines can offer significant value:

Integration into EPC Projects

As a trusted industrial supplier with over 50 years of experience, Tecnium is well-positioned to support EPC contractors like Técnicas Reunidas in the delivery of large-scale, high-spec projects. All of Tecnium’s equipment is engineered, manufactured, and tested in-house — ensuring full traceability, quality assurance, and customisation to project-specific requirements.

From design consultancy to turnkey delivery, Tecnium can seamlessly integrate into the supply chain of green ammonia plants, providing:

A reliable partner for green ammonia infrastructure

Green ammonia represents one of the most promising frontiers for decarbonising global industry and energy. As demand for hydrogen-derived fuels grows, the need for robust, safe, and efficient supporting infrastructure becomes critical. Gas scrubbing systems, corrosion-resistant pumps, and thermoplastics engineering are not peripheral — they are central to the long-term performance and safety of these facilities.

Tecnium brings over five decades of experience delivering environmental technology solutions to some of the world’s most demanding industrial sectors. Our gas treatment systems, plastic centrifugal pumps, and thermoplastic manufacturing expertise make us a valuable partner for companies involved in green ammonia and hydrogen development projects.

Are you planning or participating in a green ammonia project?

Contact our team to explore how Tecnium solutions can support your facility’s performance, regulatory compliance, and environmental goals — from FEED to commissioning.