Why Magnetic Drive Technology Matters

In industrial environments where safety, reliability, and chemical containment are critical, even a small leak can have major consequences. Traditional centrifugal pumps, which rely on mechanical seals to separate the motor from the liquid, have long been the weak point in these systems. Seal wear, corrosion, and thermal stress can lead to leakage — increasing operational risk, environmental contamination, and maintenance costs.

To solve this challenge, engineers developed a new approach: magnetic drive pumps. Instead of using a direct mechanical connection between the motor and the impeller, these pumps transfer energy through a magnetic coupling. This means there is no physical shaft penetration, and therefore, no possibility of fluid leakage.

Over the past few decades, this innovation has transformed fluid handling in the chemical, pharmaceutical, and wastewater treatment industries, where safety and reliability are paramount. Magnetic drive pumps have become synonymous with clean operation, minimal maintenance, and superior chemical resistance.

The Physics Behind Magnetic Drive Pumps

Magnetic Coupling Explained

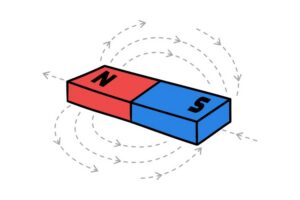

At the core of a magnetic drive pump lies a principle of physics known as magnetic coupling — the transfer of torque through magnetic fields rather than direct mechanical contact. Instead of a shaft connecting the motor to the impeller, two sets of magnets handle the job.

The outer magnet is attached to the motor shaft, and the inner magnet is attached to the impeller inside the pump casing. Between them sits a containment shell, a solid barrier that isolates the liquid from the motor. When the motor spins, the outer magnet rotates, creating a magnetic field that passes through the shell and causes the inner magnet — and therefore the impeller — to turn at the same speed.

This invisible magnetic “handshake” is what allows the pump to move fluids without any physical penetration of the casing. Since there are no seals or mechanical joints exposed to the fluid, leakage is impossible under normal operation.

How the Pump Operates Step by Step

This design makes magnetic drive pumps especially useful in processes where chemical containment, purity, and safety are non-negotiable.

Magnetic Efficiency and Design Challenges

However, magnetic coupling comes with its own engineering challenges. The distance between magnets, the strength of the magnetic field, and the properties of the containment shell all affect efficiency.

If the load becomes too high — for example, if the pump runs dry or the fluid is too viscous — the magnets can decouple, stopping the impeller. Modern designs minimise this risk through high-strength neodymium magnets and temperature-resistant containment shells made from materials such as carbon fibre composites or ceramics.

Thermal and Magnetic Efficiency

Magnetic drive pumps operate with minimal friction, but the transfer of torque through magnetic fields can induce eddy currents — small electrical loops that generate unwanted heat in conductive materials. This heat must be carefully managed to prevent energy loss and material degradation.

To combat this, modern designs employ:

As a result, the best magnetic drive pumps achieve efficiencies comparable to or exceeding traditional sealed pumps, all while maintaining zero-leak reliability and lower maintenance requirements.

Industrial Applications of Magnetic Drive Pumps

Chemical Processing

In the chemical industry, where fluids are often aggressive, toxic, or flammable, safety and reliability are non-negotiable. Magnetic drive pumps have become the standard solution for transferring acids, alkalis, chlorinated solvents, and other hazardous substances without risk of leakage.

Because they operate without shaft seals, these pumps eliminate one of the main causes of fugitive emissions and accidental releases. This makes them compliant with increasingly strict environmental regulations such as ATEX and EPA standards, ensuring worker safety and plant integrity.

Furthermore, the high chemical resistance of materials like PVDF and PFA allows them to handle concentrated sulphuric acid, sodium hypochlorite, and hydrochloric acid — fluids that would quickly degrade conventional pumps.

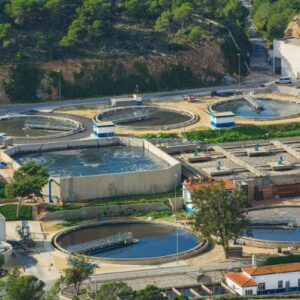

Water and Wastewater Treatment (WWTPs)

In wastewater treatment plants, magnetic drive pumps are used for dosing and transferring chemical reagents such as sodium hydroxide, ferric chloride, or hydrogen peroxide. Their leak-free operation prevents contamination of the surrounding environment, while their low maintenance requirements reduce downtime in critical treatment stages.

They are particularly effective in processes such as:

By providing a closed, corrosion-resistant transfer system, magnetic drive pumps help WWTPs comply with strict environmental standards and improve overall process safety.

Pharmaceuticals and Food Industry

In sectors requiring absolute purity, such as pharmaceuticals and food processing, magnetic drive pumps provide a completely sealed, contamination-free transfer system.

Because the liquid never comes into contact with mechanical seals or lubricants, the risk of product contamination is virtually zero.

They are used for:

In these applications, pumps made from FDA-approved materials like high-grade stainless steel or fluoropolymers ensure both compliance and performance. Additionally, their smooth internal surfaces minimise the risk of bacterial growth and make cleaning processes faster and more effective.

Optimising Industrial Performance with Magnetic Drive Pumps

Magnetic drive pumps have become an essential component in industries seeking maximum safety, reliability, and sustainability. Their ability to handle aggressive chemicals without leaks not only enhances operational safety but also helps companies comply with increasingly strict environmental and emission standards.

One of their greatest advantages lies in predictable performance. Unlike traditional sealed pumps, whose efficiency can drop as seals wear out, magnetic drive systems maintain a consistent flow rate and energy efficiency over time. This stability is particularly valuable in continuous processes such as chemical manufacturing, wastewater treatment, and surface finishing, where even minimal downtime can result in production losses

Modern magnetic drive pumps are also compatible with IoT-based monitoring systems, allowing real-time tracking of temperature, vibration, and flow rate. This integration supports predictive maintenance, helping operators identify potential issues before they cause unplanned stoppages.

By combining precision engineering, advanced materials, and smart control systems, magnetic drive pumps represent a cornerstone in the shift toward cleaner, safer, and more automated industrial operations.

Choosing the Right Pump for Industrial Safety and Sustainability

Selecting the right pump goes beyond capacity or pressure ratings — it’s about ensuring operational safety, chemical compatibility, and long-term reliability. In industries where corrosive fluids, toxic vapours, or environmentally sensitive materials are handled daily, magnetic drive pumps offer a level of protection that traditional sealed pumps simply cannot match.

By eliminating mechanical seals, these pumps reduce maintenance, prevent leaks, and extend service life, all while supporting compliance with modern environmental standards. Their adaptability to different materials and system configurations allows engineers to integrate them seamlessly into both new installations and retrofits across the chemical, water treatment, and energy sectors.

As industries continue moving toward decarbonisation and cleaner production, the role of leak-free, energy-efficient technologies will only grow more critical. Magnetic drive pumps stand at the forefront of this transition, providing a proven and reliable foundation for sustainable industrial operations.