Pumps for Uranium Mines

Uranium is the element with the highest atomic weight of the periodic table. It is present in the nature in very low concentrations (a few parts per million) in rocks, soil and water. To be used uranium must be extracted and concentrated from minerals that contain it.

Uranium ore has traditionally been obtained in open or underground mines, while the most commonly used technique today is in situ leaching (ISL) or in situ recovery (ISR).

Leaching stage can be static or dynamic. ISL technique, is performed during the extraction phase. The resulting solution PLS (Pregnant leach solution) has a greater or lesser presence of solids depending upon the technique used to obtain and requires a clarification stage.

The next step is to refine and purify uranium dissolved in the aqueous medium using resins or organic solvents through ion exchange. Finally uranium salts are obtained by precipitation, usually with ammonia. Prior to packaging and sale, a drying process is made to remove moisture resulting in a concentrated powder with 80-85 wt% of U3O8.

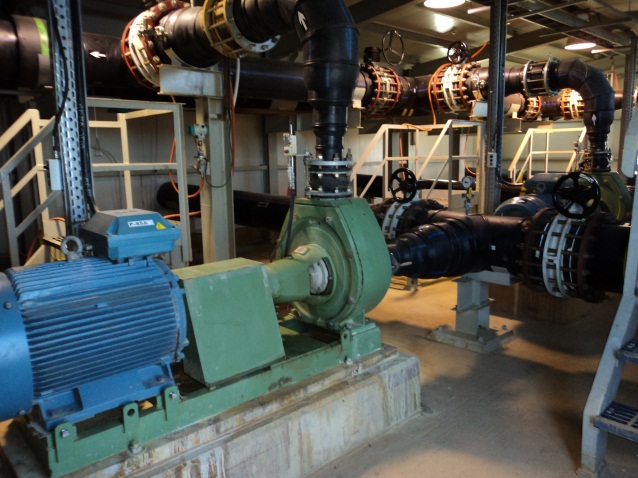

Tecnium is regular supplier of uranium production plants using in situ leaching techniques (ILS) and has more than 150 pumps installed worldwide. In this technology, uranium is washed from the place where the ore is extracted by means of acidic or alkaline solutions injected into regularly spaced wells, and recovered from the leach solution in a surface plant.

Tecnium pumps are applied, usually in cases in which the leaching solution is based on sulfuric acid and precipitation is carried out with hydrogen peroxide.

Typical applications of Tecnium within this process are:

- H2SO4 transfer to the processing plant

- Feeding to the injection wells.

- Transfer of barren solutions from leaching process

- Transfer of PLS solutions to the filtering stage

- Transfer of resin solutions

- Pump for sand solution (Sand Pond pump)

- Thickeners feed

- NH4NO3 supply

- NH3 discharge pump.

- Transfer of acidic waste solutions

- Drainage pits on filtration steps

- Drainage pits on ion exchange areas

- Emergency pits on reagent storage area

- Emergency pits on elutions area

- Drainage pits on thickeners area

More information

Give us your contact details and we will advise you on the best solution for your application.

View also

How Gas Scrubbing Technologies Will Drive Decarbonisation in the Chemical Sector

Decarbonisation as the Urgent Challenge for the Chemical Industry The chemical industry is entering one of the most transformative decades in its history. As regulatory pressure intensifies and global climate targets advance, [...]

Tecnium to attend PCH Meetings 2025 in Lyon

Leading Innovation in Chemical Process Equipment Tecnium will participate in the 21st edition of PCH Meetings, the leading international business convention for process, chemical, petrochemical, and pharmaceutical industries, to be held on [...]

Magnetic Drive Pumps: The Science Behind Leak-Free Chemical Transfer

Why Magnetic Drive Technology Matters In industrial environments where safety, reliability, and chemical containment are critical, even a small leak can have major consequences. Traditional centrifugal pumps, which rely on mechanical seals [...]

Biofiltration for Air Pollution Control

Introduction to Biofiltration and Air Pollution Control Air pollution control is a persistent challenge across multiple industries — from wastewater treatment to chemical manufacturing, food processing, and beyond. As regulations grow stricter [...]

ECHA 2025 Report

Why the ECHA 2025 Report Matters The European Chemicals Agency (ECHA) plays a central role in regulating the safe use of chemicals across the European Union. Through its guidance, risk assessments, and [...]

A Key Element for Environmental Protection in WWTPs

Why Gas and Odour Emissions in WWTPs Are an Environmental Issue Wastewater treatment plants (WWTPs) play a critical role in safeguarding public health and the environment. However, the treatment process itself can [...]